Plastic machinery is a cornerstone of the manufacturing industry, enabling the production of a diverse range of plastic products. However, like any mechanical system, plastic machinery can encounter issues that impact its performance. In this guide, we’ll delve into common problems faced in plastic machinery and provide effective troubleshooting solutions to keep your operations running smoothly.

Introduction

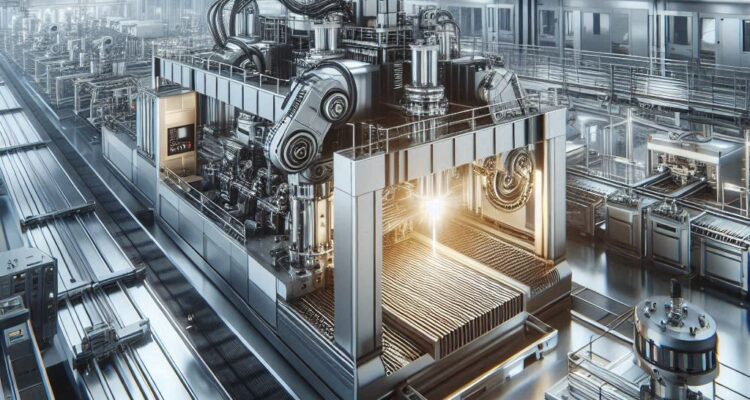

Plastic machinery, encompassing injection molding machines, extruders, and blow molding machines, is integral to the manufacturing process. Identifying and resolving issues promptly is crucial for maintaining productivity and ensuring the longevity of your machinery.

Common Issues and Troubleshooting Solutions

Injection Molding Defects:

Extrusion Problems:

Inconsistent Product Quality:

Machine Jamming:

Overheating Issues:

Hydraulic System Failures:

Electrical Failures:

Preventive Measures for Long-Term Efficiency

To minimize the occurrence of these issues, implement proactive measures. Regular maintenance, employee training, and investing in quality components contribute to the overall efficiency and reliability of your plastic machinery.

Conclusion

Addressing common issues in plastic machinery demands a systematic approach and a comprehensive understanding of the equipment. By promptly resolving issues and implementing preventive measures, you can enhance the performance and longevity of your plastic machinery, contributing to the success of your manufacturing operations.

Keval Machine Tools – Your Trusted Partner in Plastic Machinery SolutionsAt Keval Machine Tools, we recognize the importance of maintaining optimal plastic machinery performance. With our expertise and commitment to quality, we offer comprehensive solutions to address and prevent common issues, ensuring the seamless operation of your plastic manufacturing processes.