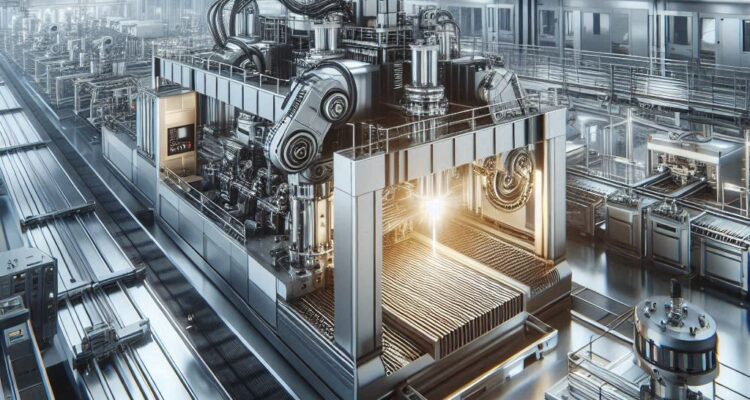

Workshop machinery is indispensable in various industries, facilitating manufacturing and fabrication processes. However, ensuring the safety of workers operating and working around these machines is of paramount importance. In this comprehensive guide, we’ll delve into essential safety measures to be implemented in workshop machinery environments.

Workshop machinery, including lathes, milling machines, and drill presses, can pose potential risks if not used and maintained properly. Prioritizing safety not only protects workers but also contributes to increased productivity and a healthier work environment.

Each type of workshop machine presents unique risks. Identify and understand the potential hazards associated with specific machines, such as rotating parts, sharp edges, and electrical components.

Beyond machine-specific risks, workshops may have common hazards like slippery floors, inadequate lighting, or improper ventilation. Conduct a thorough risk assessment to address these general dangers.

Well-trained and informed employees are the first line of defense against accidents. Provide comprehensive training programs covering machine operation, emergency procedures, and the proper use of personal protective equipment (PPE).

Schedule routine inspections to identify and address any wear and tear, malfunctioning parts, or potential issues with workshop machinery. Prompt repairs and maintenance help prevent accidents caused by faulty equipment.

Install appropriate guards and safety devices on machines to protect operators from moving parts. Machine guarding is a crucial aspect of workshop safety and helps minimize the risk of injuries.

Establish well-equipped first aid stations within the workshop. Train staff in basic first aid procedures and ensure that necessary supplies are readily available to address minor injuries promptly.

Develop and regularly practice emergency evacuation plans to ensure a quick and orderly response in case of fire, machinery malfunction, or other unforeseen incidents.

Launch regular safety awareness campaigns to keep employees informed about the latest safety protocols, potential hazards, and best practices in workshop machinery safety.

Implement a clear and accessible system for reporting safety concerns or incidents. Encourage employees to report any unsafe conditions promptly, fostering a proactive approach to safety.

In conclusion, prioritizing safety in workshop machinery environments is not just a legal requirement; it’s a fundamental responsibility. By understanding potential hazards, implementing safety protocols, and promoting a safety culture, workshops can create a secure and productive working environment for all.

Keval Machine Tools – Committed to Workshop Safety

At Keval Machine Tools, we prioritize the safety of your workforce. Our workshop machinery solutions adhere to the highest safety standards, ensuring a secure and efficient working environment. Contact us for reliable and safe workshop machinery options.