Description:-

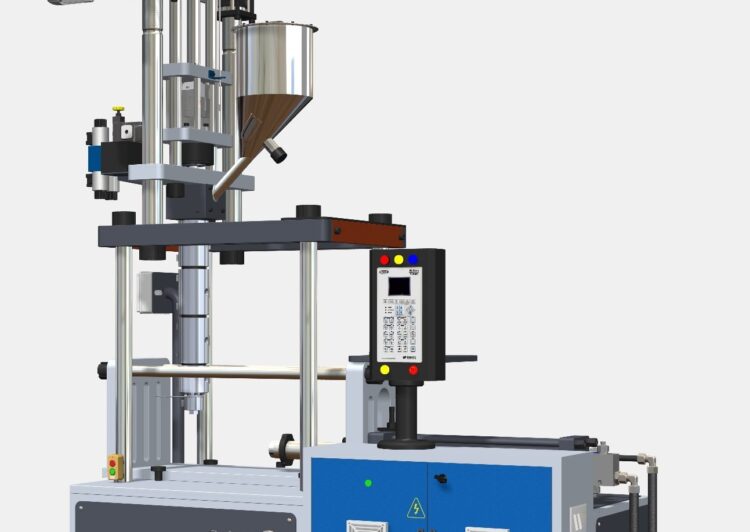

A hand injection molding machine, also known as a manual injection molding machine, is a small, manually operated machine that is used for making small plastic parts. It is a simple device that consists of a barrel, plunger, and a mold cavity. The operator manually injects the plastic material into the mold cavity using a hand-operated lever or pump.

Hand injection molding machines are commonly used for small-scale production or prototyping, as they are more affordable and portable than larger, automated machines. They are also useful for making small quantities of parts or for molding parts with intricate geometries that may be difficult to produce with other molding methods.

While hand injection molding machines have some advantages, they also have limitations. For example, they can only produce small parts and are not suitable for high-volume production. Additionally, they require a skilled operator who can carefully control the injection process to ensure consistent quality.

| Moulding Capacity | Production Rate Per Hour | Heat Consumption(approx) | Mould Weight (In Grams) | Mould Size | Machine Measurement | Approx | |||

| Length | Height | Length | Width | Height | Weight | ||||

| 3/8 oz | 130 pcs | 400 Watts | 1 to 8 | 4.1/2" | 5" | 16.1/2" | 6.1/2" | 21.1/2" | 38 kg |

| 1/2 oz | 110 pcs | 600 Watts | 8 to 15 | 5.1/2" | 6" | 18" | 8" | 27" | 60 kg |

| 1 oz | 70 pcs | 700 Watts | 10 to 30 | 8" | 8" | 25" | 9.1/2" | 30" | 85 kg |

| 1.1/2 oz | 60 pcs | 1000 Watts | 20 to 40 | 10" | 12" | 30" | 10.1/2" | 39" | 130 kg |

| 2 oz | 40 pcs | 1200 Watts | 20 to 60 | 10.1/2" | 14" | 31" | 11" | 42" | 180 kg |